Characteristics of Servo energy-saving injection molding machines

1. High energy saving

In an ideal working state, compared with conventional injection molding machines, their

Energy saving can reach 20%-80%.

2. Better molding stability

Compared with conventional injection molding machines, repeatability is greatly improved.

Adopt to servo motor closed-loop control.

3. Quick response

Sensitive servo motor, the response time only 0.05 second.

4. Quiet & low noise

The machine runs with low noise, and will be much quieter in a low speed.

5. Reliable holding pressure

Compared with all electric injection molding machines, the time for pressure holding will be much longer and steady.

6. Oil temperature rise slowly

Servo motor proportionally deliver hydraulic oil base on our needs, it can prevent unnecessary.Heat being generated, even in some cases does not require cooling.

Excellency of this series machine:

A: High rigidity, excellent performance, and fast response, energy efficient and durable.

B: Products have obtained praise and good comment from domestic and foreign customers with its excellent service and quality.

C:We use high-quality of steel casting for the machine.

D:We have testing equipment for testing the material such as the plate.

E::The front and moving plate has T-slot, it is easy for change mould.

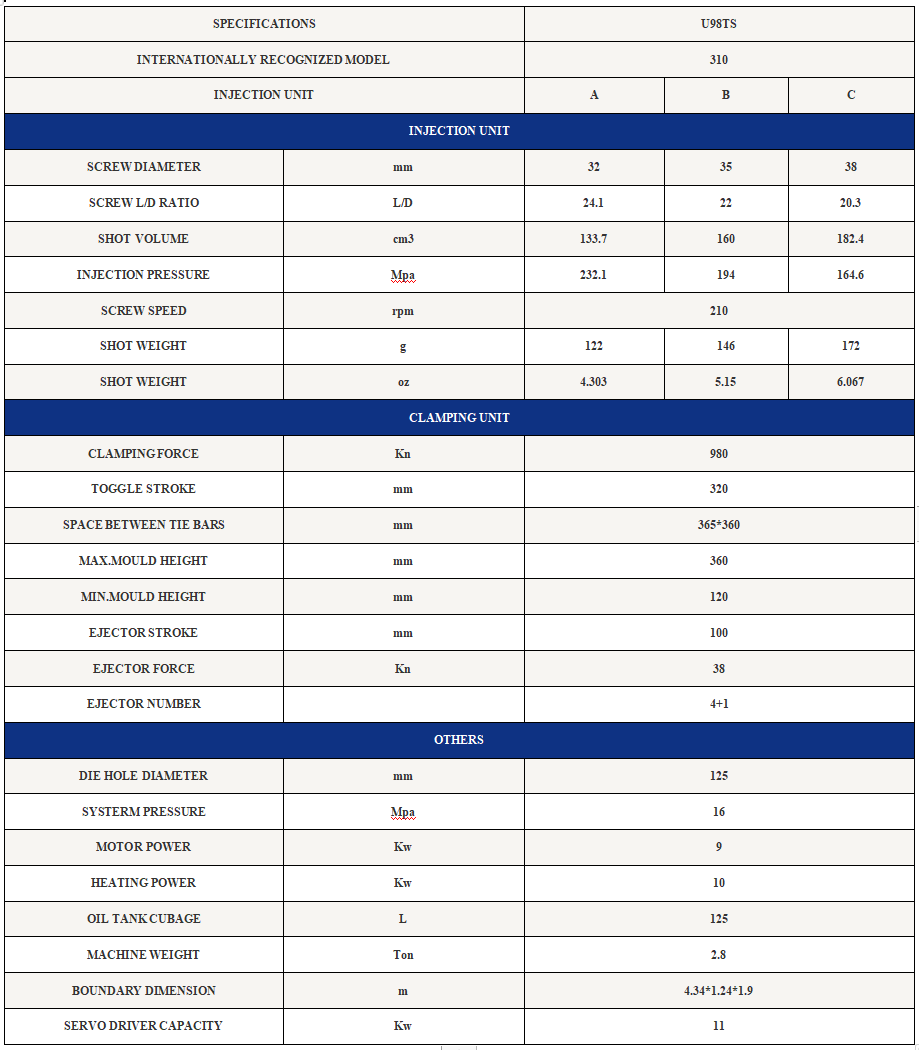

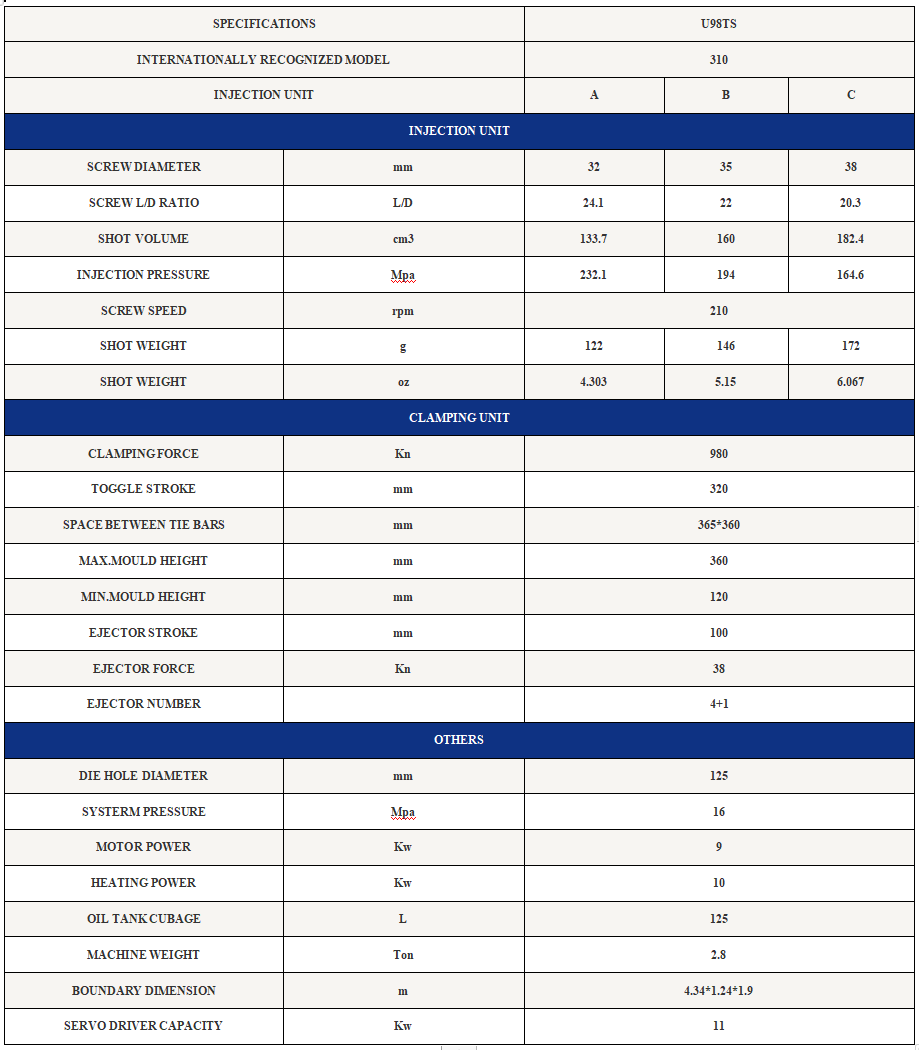

Clamping unit:

1. Internally-rolled 5-point double toggle mold clamp structure, greatly increases rigidity and precision of the mold clamp unit.

2. With box type bridge structure, moving platen, and high rigidity continuous rear platen reinforced through finite-element analysis, we guarantee that the mold platens are not deformable and are durable.

3. The tie rods are made of high quality structural alloy steel plated with hard chromium, with high mechanical strength and fatigue strength.

4. Provided with low-pressure mold protection device.

5. Multi stages controlling of mold clamp pressure, speed and position.

6. Mold thickness adjusted through ring gear driven by hydraulic oil motor.

7. Several hydraulic ejection modes.

Injection unit:

1. Use of double guide posts and dual-cylinder balance injection device, guarantees that balanced and uniform forces are applied on the screw during injection and moving forward.

2. High quality alloy screw nitride or with chromium plating, and nitride barrels, are protected against corrosion and fatigue, which greatly increase their service life.

3. With fine adjustment of nozzle centering.

4. Screw preplasticizing driven by high torque hydraulic motor device.

5. Multiple injection speed, pressure and position settings.

6. Special screws and barrels are provided according to different properties of engineering plastics to ensure the molding quality of finished products.

Lubrication unit:

1. With use of volumetric electrical lubricator, automatic centralized lubrication and uniform oil distribution in the pipeline, the machines have high lubrication efficiency and long toggle life. Hydraulic unit:

2. Well-known oil pump and control valves in the world are used, to execute accurate controlling over the force, speed and direction of hydraulic mechanism and ensure the accuracy, reliability, stability and durability of the machine.

3. Control system of the constant displacement pump ensures steady outputs and high response.

4. Main hydraulic elements and seals are international well-known brands.

5. The pipelines are arranged more reasonably and better, and thus ensure easy maintenance.

Main Features:

One.The Lock Section

1.Arch template, effectively protects the mould, especially suitable for big template with small mold.

2.The electric ruler is installed on the crosshead, the position is more precise.

3.The front connecting rod uses connected structure, increases the rod strength, and easy for assembly

4.The connected tail-board stills itself with big lock shaft, improves tail-board strength, and ensures zero abrasion of the tail-board, easy for maintenance.

5.Connected movable plate, improves its rigidity and reduces deformation

6.Connected thrust bearing, improves its strength and stills itself with small lock shaft, ensures zero abrasion.

7.Arch template fully complies with mechanical property, largely improves template strength.

8.More reasonable toggle design, speeds and stabilizes mold opening and closing.

9.Adjustable movable plate mounting plate, makes the installation easier.

10.Mixed design of T-shape groove and die hole, increases universality of the mold.

Two.The Injection Section.

1.Bridge type support, improves injection smoothness.

2.Longer length-diameter ratio screw design, improves plasticizing effect.

3.Double seal structure, ensures no oil leakage.

4.Withhold type press plate, easy for debugging and assembly.

5.Bijection structure, improves stability.